Why is acetone safety so important in many industries? How can we prevent accidents and protect the environment by storing and disposing of acetone properly? Knowing how to handle acetone safely is crucial for a safe workplace. This solvent is widely used but can be dangerous if not stored and disposed of correctly. Keeping acetone safe involves more than just storing it right. It’s about a whole approach that includes how to dispose of it, using good ventilation, and choosing the right containers. By focusing on acetone safety, we can lower the risks it poses and make our workplaces safer. Storing and disposing of acetone properly helps avoid accidents and keeps our environment safe.

Click to buy citric acid from Silvairgroup

Key Takeaways:

- Acetone safety is crucial for preventing accidents and minimizing environmental impact

- Proper acetone storage is essential for reducing health and environmental risks

- Acetone disposal methods must be handled correctly to prevent accidents

- Understanding the properties and uses of acetone is vital for safe handling

- Proper ventilation and container selection are critical for acetone safety

- Acetone safety requires a comprehensive approach that includes storage, disposal, and handling procedures

Understanding Acetone and Its Properties

Acetone is a chemical used in many industries. It’s important to know how to handle it safely. Acetone handling precautions help avoid accidents and reduce exposure. Its flammability and solvency make it useful but also dangerous. Acetone is used in nail polish removers, cleaning, and as a solvent. But, it can cause health problems like skin irritation and breathing issues.

Chemical Properties of Acetone

Acetone is a VOC with high vapor pressure. Its properties make it a good solvent but also risky for health and the environment. Key properties include:

- High flammability

- High solvency

- Low boiling point

Common Uses and Applications

Acetone is used in many fields, such as:

- Cosmetics and personal care products

- Pharmaceuticals and medical devices

- Manufacturing and industrial processes

Potential Hazards and Risks

Being exposed to acetone can cause health problems, including:

- Skin irritation and dermatitis

- Respiratory problems and asthma

- Neurological effects and headaches

Click to buy Citric Acid Anhydrous from Silvairgroup

Following acetone handling precautions and acetone ventilation guidelines is crucial. This way, we can handle acetone safely and avoid accidents.

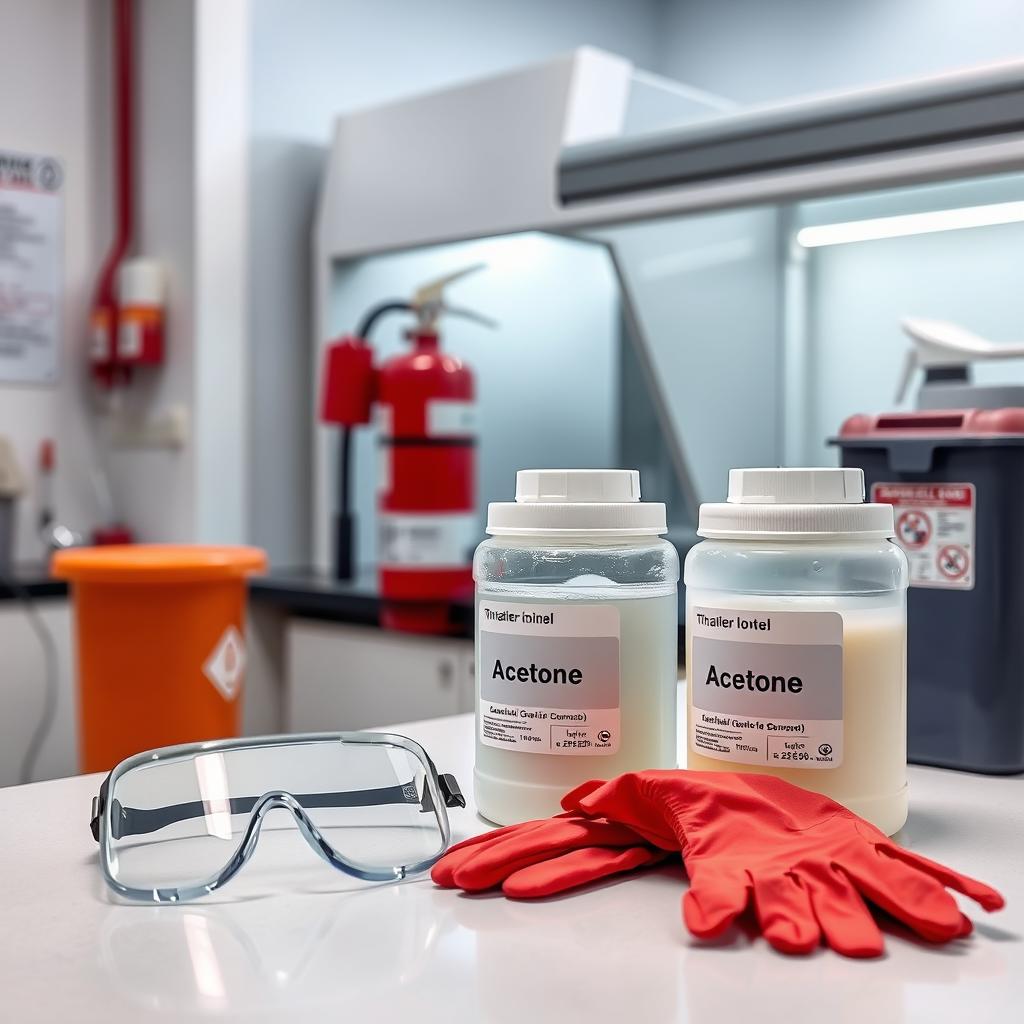

Essential Safety Equipment for Handling Acetone

Handling acetone requires careful attention to safe acetone usage to avoid risks. It’s important to wear gloves, safety glasses, face masks, and protective clothing. Also, make sure the area is well-ventilated to avoid acetone vapors. Some key safety items for acetone include:

- Gloves to prevent skin contact

- Safety glasses to protect the eyes

- Face masks to prevent inhalation of vapors

- Protective clothing to prevent skin exposure

Click to buy liquid Citric Acid from Silvairgroup

It’s also crucial to follow best practices for acetone storage. Store acetone in well-ventilated areas, away from heat and flames. Regular equipment checks and proper training are also essential for a safe work environment. By focusing on safe acetone usage and proper storage, we can reduce risks. This ensures a safe and healthy work environment.

| Safety Equipment | Description |

|---|---|

| Gloves | Prevent skin contact with acetone |

| Safety Glasses | Protect the eyes from acetone splashes |

| Face Masks | Prevent inhalation of acetone vapors |

| Protective Clothing | Prevent skin exposure to acetone |

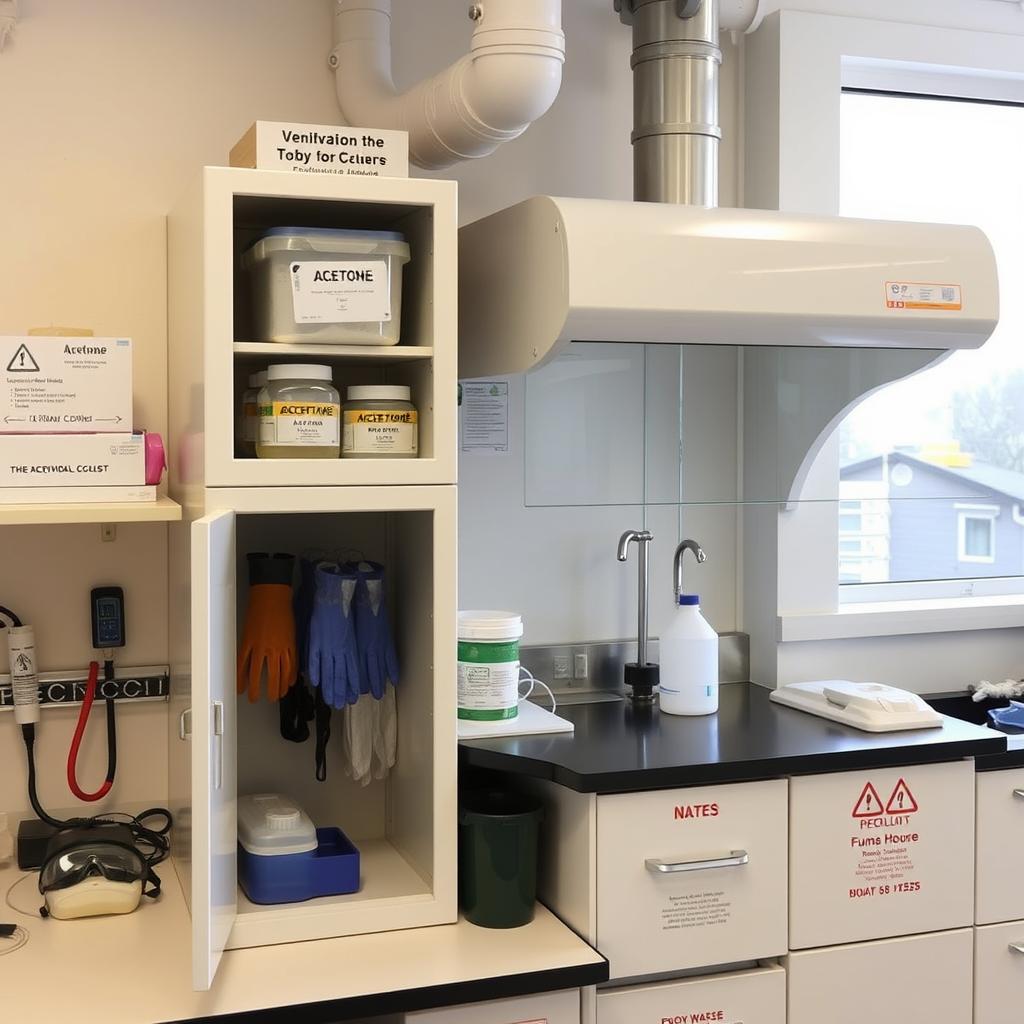

Proper Ventilation Requirements for Acetone Storage

Storing acetone requires following acetone ventilation guidelines to avoid vapor buildup. This can cause explosions or health problems. It’s vital to have good ventilation to keep the work area safe and prevent preventing acetone exposure. Health guidelines say storage areas should have fast air exchange. To ensure safety, remember these important points:

- Ensure good airflow in storage areas

- Use ventilation systems that can exchange air quickly

- Regularly inspect and maintain ventilation systems

Indoor Ventilation Guidelines

Indoor storage needs careful planning for ventilation. Install systems that exchange air fast and check them often. This keeps them working right.

Click to buy frozen a grade beluga fish from Silverigroup

Outdoor Storage Considerations

Outdoor storage must be in well-ventilated spots, away from fire risks. It’s also key to monitor air quality often. This makes sure acetone levels stay safe, preventing preventing acetone exposure.

Acetone Safety: Proper Storage and Disposal Methods

Proper storage and disposal of acetone are key to keeping our environment safe and healthy. Acetone is very volatile and flammable. It needs careful handling to avoid accidents and harm to our health. To keep things safe, use containers that are approved and tightly sealed. Store them in a cool, well-ventilated area. Make sure to label them and keep them away from harmful substances. Here are some important tips for storing and disposing of acetone:

- Use approved containers that are tightly sealed and stored in a cool, well-ventilated area.

- Label containers and keep them away from incompatible substances.

- Dispose of acetone and acetone-contaminated materials according to local and national regulations.

- Consider using hazardous waste facilities for disposal.

By following these steps, we can keep acetone safe and prevent harm to our environment. Always check local and national waste management and safety rules to make sure we’re doing the right thing.

Container Selection and Storage Conditions

Choosing the right container for acetone is key. It must be safe for acetone, not leak, and handle its corrosive nature. This is why best practices for acetone storage are so important. Here are some things to think about for safe storage:

- Material compatibility: The container should be made of a material that is resistant to acetone’s corrosive properties.

- Leak-proof design: The container should be designed to prevent leaks and spills, reducing the risk of accidents.

- Temperature control: Acetone should be stored in a cool, dry place, away from direct sunlight and heat sources.

Following these acetone handling precautions helps lower risks. It’s also crucial to have a special area for hazardous materials. This area should have clear signs and limited access. Proper storage is essential for a safe work area. By using best practices for acetone storage and taking acetone handling precautions, you can avoid accidents. This ensures a safe work environment.

Safe acetone storage comes from the right container and conditions. By focusing on these, you can lower risks and keep your work area safe.

Safe Handling Procedures During Use

When you handle acetone, it’s key to follow safe steps to avoid accidents. This means wearing gloves and safety glasses. Also, use acetone in areas with good air flow to avoid fume buildup. To lower the chance of preventing acetone exposure, take these steps:

- Use tools and equipment designed to minimize spills and splashes

- Regularly clean and decontaminate surfaces and equipment

- Ensure good ventilation in the work area

By sticking to these tips, workers can cut down on acetone exposure risks. It’s also vital to get regular training on safe acetone usage and preventing acetone exposure. This keeps the workplace safe.

Emergency Response and Spill Management

If there’s an acetone spill, acting fast is key. First, get everyone out of the area and stop the spill from spreading. This step is vital to avoid accidents and harm to the environment.

Next, have trained people clean up the spill. They should wear gloves, goggles, and a mask to stay safe. Cleaning should happen in a place with good air flow to avoid acetone fumes.

Immediate Actions for Spills

- Evacuate the area immediately

- Contain the spill to prevent it from spreading

- Call for trained personnel to clean up the spill

Cleanup Procedures

To clean up, use a neutralizing agent like baking soda. Then, wash the area with soap and water to get rid of any acetone left. It’s important to follow these steps to keep everyone safe and protect the environment.

Documentation Requirements

After cleaning up, document the spill. Include how much acetone was spilled, how it was cleaned, and any injuries or damage. This record is important for following rules and keeping workplaces safe.

Environmental Considerations for Acetone Disposal

Acetone disposal methods have big environmental impacts. The Environmental Protection Agency gives rules for disposing of acetone and things contaminated with it. It’s key to follow these rules to avoid harming the environment for a long time. Important things to think about when disposing of acetone include:

- Using licensed places for throwing away hazardous waste

- Following local and national rules for acetone disposal

- Using the right ways to store and handle it to avoid spills and leaks

By sticking to these guidelines and thinking about the environment, we can all help protect it. It’s very important to think about the environment when getting rid of acetone. We should use the best ways to handle and throw away acetone. This means using the right containers, labeling them well, and following local and national rules.

| Acetone Disposal Method | Environmental Consideration |

|---|---|

| Incineration | Must be done in a licensed place with the right air pollution controls |

| Landfill Disposal | Must be done in a licensed landfill with the right leachate collection and treatment |

Legal Requirements and Regulations

Acetone safety rules are in place to protect everyone from its dangers. Following these rules is a must. It helps avoid fines and keeps the workplace safe. There are many rules for handling, storing, and getting rid of acetone. Federal guidelines set a basic safety standard. But, state-specific requirements can differ. Knowing these rules is key to staying safe and protecting the environment.

Federal Guidelines

OSHA sets federal rules for acetone safety. These rules cover how to ventilate, store, and handle acetone properly.

State-Specific Requirements

States have their own rules, like needing permits for acetone storage and disposal. It’s important to know these to avoid fines and follow the law.

Documentation and Reporting

Keeping accurate records of acetone use and disposal is crucial. This includes logging storage, use, and disposal. Also, report any spills or accidents to the right people. By following acetone safety rules, businesses can keep their workers safe. They also reduce environmental harm and avoid fines.

| Regulation | Description |

|---|---|

| Federal Guidelines | Provide a framework for acetone safety |

| State-Specific Requirements | May include additional regulations, such as permits and licenses |

| Documentation and Reporting | Critical for compliance with legal requirements |

Best Practices for Workplace Implementation

It’s key to follow best practices for acetone handling and storage at work. This means regular training for everyone, keeping equipment in good shape, and following safety rules. It’s also important to create a safe work culture where people feel free to report any dangers. Some important best practices for acetone storage include keeping it in areas with good air flow. Make sure it’s away from heat and open flames. Use the right containers and label them correctly. Also, teach employees how to safely use acetone, including how to handle spills and emergencies.

- Regular training for employees on acetone handling and storage

- Maintenance of equipment and safety gear

- Adherence to safety protocols and procedures

- Encouraging a culture of safety and reporting hazards

By sticking to these best practices, workplaces can lower the risks of using acetone. It’s also crucial to keep up with the latest rules and guidelines for storing and handling acetone.

Training and Education Requirements

Acetone safety training is key to a safe work place. It’s important to teach employees about acetone’s dangers. They need to know how to handle it safely and what to do in emergencies.

Employee Safety Training

Training on acetone handling should be thorough. It should cover storage, use, and disposal. A qualified teacher should lead the training, which should include practical exercises and written tests.

Documentation and Certification

It’s vital to keep records of employee training. Certifying trained employees is also crucial. This ensures they know how to handle acetone safely. Certifications should be updated often to reflect new rules and practices. Some important parts of acetone safety training include:

- Understanding acetone’s properties

- Learning safe handling practices

- Knowing emergency procedures

- Learning about storage and disposal

It’s also important to have regular refresher courses. This keeps employees up-to-date with new rules and best practices. It helps prevent accidents and keeps the work place safe.

| Training Topic | Frequency | Duration |

|---|---|---|

| Acetone safety training | Annually | 2 hours |

| Refresher course | Every 6 months | 1 hour |

Conclusion

Ensuring acetone safety is a big job that needs careful attention and a detailed plan. Knowing what acetone is, how to store it right, and how to get rid of it safely is key. This helps lower the dangers of using acetone. Training regularly, wearing the right safety gear, and always focusing on safety are crucial. They help keep workers, the public, and our environment safe.

This guide has shown how important it is to handle acetone safely. It’s all about using the right storage and disposal methods. By staying up-to-date, making good policies, and promoting a safety-first culture, companies can manage acetone safely. Being careful and paying close attention to details helps reduce the risks of this useful chemical. This way, we can all stay safe.

FAQ: Acetone Safety: Proper Storage and Disposal Methods

What are the key safety considerations for handling acetone?

When working with acetone, always wear protective gear like gloves and safety glasses. It’s also important to have on protective clothing. Make sure the area is well-ventilated to avoid breathing in acetone vapors.

How should acetone be stored safely?

Acetone needs to be kept in sealed containers in a cool, well-ventilated spot. Keep it away from heat and other materials that could react with it. The storage area should be marked for hazardous materials and have limited access.

What are the proper methods for disposing of acetone and acetone-contaminated materials?

Dispose of acetone and contaminated materials through licensed hazardous waste facilities. Always follow local and national regulations. Wrong disposal can harm the environment and lead to legal trouble.

What are the recommended ventilation requirements for acetone storage?

Areas where acetone is stored indoors should have good ventilation systems. These systems should quickly change the air to prevent vapors from building up. Outdoor storage should also be in well-ventilated spots, away from fire risks. It’s important to check the air quality regularly.

What personal protective equipment (PPE) is required when handling acetone?

Workers handling acetone need to wear gloves, safety glasses, and protective clothing. This helps prevent skin contact, eye exposure, and inhaling vapors.

What steps should be taken in the event of an acetone spill?

If there’s an acetone spill, first evacuate the area. Then, contain the spill to stop it from spreading. Use the right equipment and protective gear to clean it up. Finally, document the incident for regulatory compliance.

What are the legal requirements for the storage and disposal of acetone?

Handling, storing, and disposing of acetone must follow federal and state laws. These laws protect workers, the public, and the environment. It’s crucial to comply with these regulations and keep proper records.