In the world of carpet design, wool is a true luxury icon. It’s a natural wonder that top homeowners and designers love. But why is wool so special as a carpet material? Let’s explore the secrets behind its timeless charm.

Click to use Silverigroup personal shopper services

Key Takeaways:

- Wool is a premium natural fiber prized for its exceptional qualities in carpet manufacturing.

- The chemical composition and inherent properties of wool make it an ideal choice for luxurious, long-lasting carpets.

- Wool’s environmental benefits, such as biodegradability and sustainability, further enhance its appeal in the modern era.

- Understanding the processing steps and global supply chain of wool carpet raw material is crucial for discerning consumers.

- The quality grading and regional variations of wool significantly impact the final carpet’s performance and aesthetic.

Understanding Wool as a Premium Carpet Fiber

Wool is a top choice for making high-quality carpets. It has special properties that make it perfect for luxury carpets. As people want more eco-friendly home items, wool’s green benefits make it even better.

Chemical Composition of Wool Fibers

Wool fibers are mostly keratin, a protein that makes them soft and stretchy. This lets wool take dyes well, creating bright and lasting colors. The scales on wool fibers also help them stick together, making carpets strong and long-lasting.

Natural Properties That Make Wool Ideal

- Exceptional softness and comfort underfoot

- Inherent stain and soil resistance

- Excellent insulation properties, keeping homes warm in winter and cool in summer

- Natural flame retardancy, enhancing safety in the home

Click to buy citric acid from Silvairgroup

Environmental Benefits of Wool Selection

Wool is good for the planet because it’s renewable and can break down naturally. It doesn’t harm the environment like synthetic fibers do. Plus, wool carpets can be recycled or composted, helping to reduce waste.

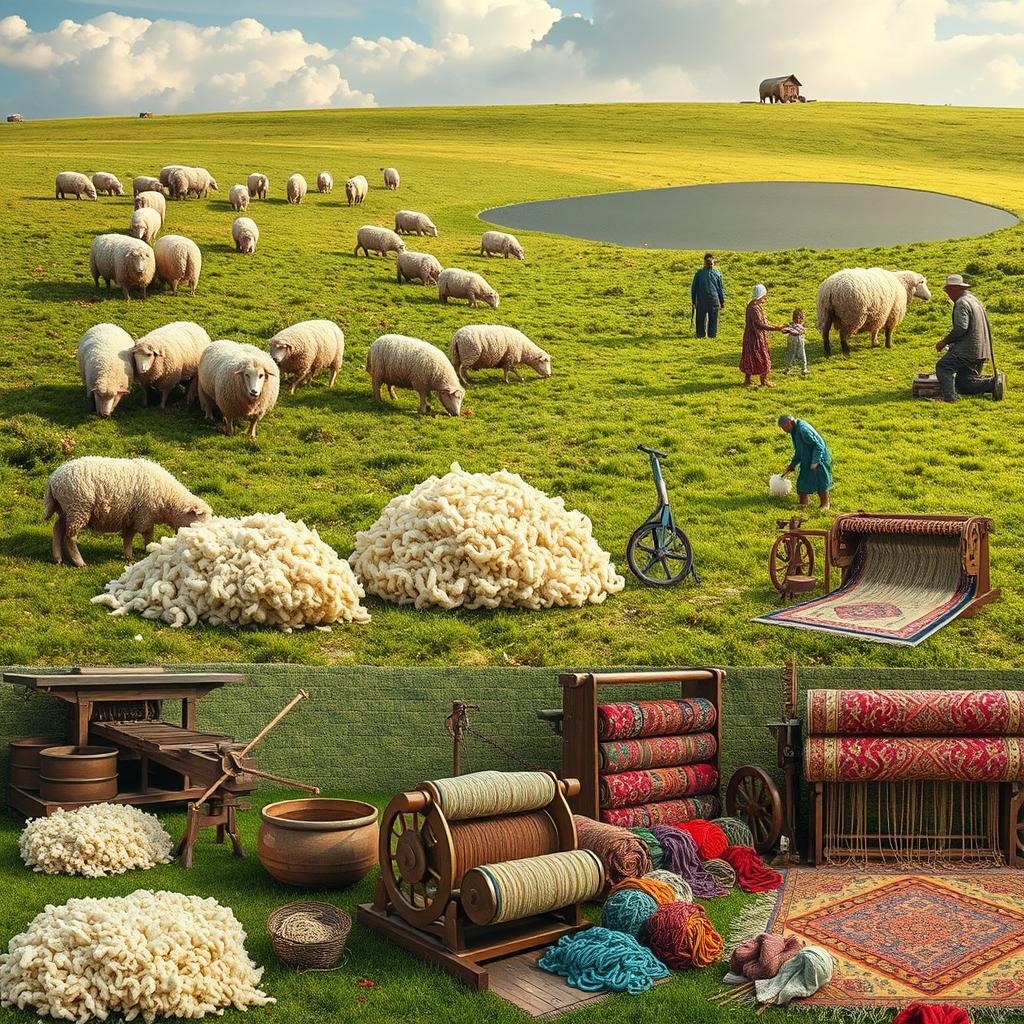

The Journey from Sheep to Carpet: Wool Processing Steps

Turning raw wool into a top-notch carpet is a detailed process. It involves many steps. This journey shows the skill and care in making great floor coverings.

First, sheep are sheared to get the wool fleece in one piece. Then, the wool is scoured to clean it. This removes dirt, grease, and other impurities, making the fibers clean for the next step.

- Carding: The scoured wool is carded. This aligns the fibers into a smooth web.

- Spinning: The carded wool is spun into strong, uniform carpet manufacturing yarn. This is a key step in making the wool usable.

- Dyeing: The yarn is dyed to get the right colors. This lets wool carpet mills make many different hues and patterns.

- Weaving: The yarn is woven into the carpet. This is the last step, turning the wool into a beautiful floor covering.

Click to buy frozen a grade beluga fish from Silverigroup

This detailed process has been perfected over centuries. It’s the heart of the wool carpet industry. It makes carpets that are luxurious, durable, and good for the environment for homes and businesses everywhere.

| Wool Processing Step | Description |

|---|---|

| Shearing | Carefully removing the wool fleece from the sheep in a single piece. |

| Scouring | Cleaning the raw wool to remove dirt, grease, and other impurities. |

| Carding | Combing and aligning the wool fibers to create a smooth, consistent web or “lap”. |

| Spinning | Transforming the carded wool into sturdy, uniform carpet manufacturing yarn. |

| Dyeing | Applying dyes to the yarn to achieve the desired color palette. |

| Weaving | Skilled weaving of the dyed yarn into the final carpet structure. |

Quality Grades of Wool Carpet Raw Material

The world of wool carpet making is full of interesting facts. It has many top-quality wool types, different regions, and how wool grade affects carpet quality. Knowing these details is key for those who love carpets and work in the industry.

Premium Wool Classifications

At the top, we have Merino wool. It’s known for being very soft, fine, and strong. This makes it perfect for the most luxurious carpets. Other top types like Saxony and Shetland wool are also sought after for their special qualities and rarity.

Regional Wool Variations

Wool from different places can be very different. For example, wool from the Scottish Highlands is strong and coarse. It’s great for tough carpets. On the other hand, wool from the Himalayas is soft and silky. It’s perfect for detailed, high-end carpets. Knowing these differences helps carpet makers create carpets that show off their unique origins.

Impact of Wool Grade on Carpet Quality

The quality of the wool used affects the carpet’s look, feel, and how well it lasts. High-quality wools like Merino make carpets softer, keep colors better, and last longer. Lower-quality wools might cause carpets to shed, fade, and wear out faster. People who choose carpets often look for the best wool grades because they know they’re getting a good value for their home.

Global Wool Carpet Raw Material Suppliers

The global market for wool carpet raw materials is full of variety. Suppliers from all over the world meet the carpet industry’s needs. From New Zealand’s hills to Australia’s rugged lands, these suppliers are key to making top-notch wool carpets.

The Australian Wool Exchange is a top wool carpet raw material supplier. They get their wool from Australia’s vast pastures. Australian wool is famous for its quality and lasts a long time, making it a favorite among carpet makers.

New Zealand’s wool industry is also well-known for its quality and green practices. Companies like Wool Partners International and Alliance Group are big names. They provide wool carpet raw materials that meet the industry’s high standards.

In the United States, the American Sheep Industry Association (ASI) connects wool carpet raw material suppliers. They use the country’s long history of wool production. These suppliers work with carpet makers to ensure top-quality carpet raw materials are always available.

Suppliers from Argentina, Uruguay, and the United Kingdom are also growing in the carpet raw materials market. Each brings their own special types of wool and ways of processing it. As more people want wool carpets, the importance of these wool carpet raw material suppliers grows. They help meet the changing needs of the industry. They provide the best carpet raw materials for making beautiful, lasting floors.

Traditional Persian Carpet Wool Requirements

The world of fine carpets is special, and Persian carpets stand out. They are known for their amazing craftsmanship, detailed designs, and top-quality wool carpet raw material. Choosing the right wool is key to making these stunning wool carpet pieces.

Special Characteristics of Persian Wool

Persian wool comes from Iran’s mountains and is known for its high quality. It has:

- Exceptional luster and sheen, making the carpet look great

- Inherent durability and resilience, keeping the carpet lasting long

- Naturally crisp and springy texture, making the carpet feel good

- Vibrant and rich colors that dye well, creating beautiful patterns

Historic Wool Selection Methods

Choosing the right wool carpet raw material is a long-standing tradition in Persian carpet making. Master weavers would pick the finest wool fibers with great care. They used old techniques and knowledge passed down through generations. These methods included:

- Carefully inspecting the wool for quality, like fiber length and thickness

- Testing the resilience and springiness of the wool for durability

- Picking wool from specific sheep breeds for its exceptional fleece

- Mixing different wool types to get the right texture and color

The focus on detail and using the best wool carpet raw material made traditional Persian carpet weaving famous. It has led to the creation of timeless masterpieces that amaze people all over the world.

Modern Wool Carpet Manufacturing Techniques

In the world of carpet manufacturing, making wool carpets has changed a lot. Today’s wool carpet mills use new tech and better ways to work. This has made the industry better and the carpets top-notch. One big change is the use of automated tufting machines. These machines put wool tufts into the carpet backing perfectly. This makes the carpet look better and last longer.

Another big step is in dyeing. Wool carpet mills now use computers to control dyeing. This means colors are more vibrant and designs last longer. It also lets them make unique patterns and colors for different tastes.

| Technique | Benefit |

|---|---|

| Automated Tufting | Consistent loop height and density for enhanced durability and visual appeal |

| Computer-Controlled Dyeing | Precise color control for vibrant and long-lasting carpet designs |

| Innovative Backing Systems | Improved dimensional stability and reduced shedding for a superior carpet experience |

Also, new backing systems have been developed. These backings make the carpet more stable and less likely to shed. This makes the carpet better for homes and businesses. As the wool carpet production field grows, these new methods improve the carpets and make making them faster and cheaper. These modern wool carpet manufacturing methods have started a new era of quality. They meet the high standards of today’s carpet lovers.

Price Factors in Wool Carpet Raw Materials

The cost of wool carpet raw materials changes due to many factors. These include market changes, transport costs, and storage needs. Knowing these factors is key for both makers and buyers of wool carpets.

Market Fluctuations and Trends

The price of wool, a top choice for carpets, can change a lot. Global demand, weather, and the economy all play a part. Keeping up with these wool carpet raw material price changes is vital for makers to stay competitive and keep their wool carpet production going strong.

Transportation and Storage Costs

Transporting and storing carpet raw materials like wool also affects prices. Costs like fuel, shipping, storage, and handling add up. Makers need to manage these costs well to offer wool carpet at good prices.

| Factor | Impact on Wool Carpet Raw Material Price |

|---|---|

| Global Wool Supply | Scarcity can drive up prices, while surplus can lead to lower costs |

| Transportation Costs | Fuel prices, freight rates, and handling charges can increase overall costs |

| Storage and Warehousing | Fees for storing and maintaining raw wool can add to the final price |

| Regional Wool Variations | Certain wool types, such as those used in Persian carpets, may command higher prices |

By understanding these carpet raw materials price factors, makers and buyers can make better choices. This helps the wool carpet industry stay strong for the long term.

Sustainable Practices in Wool Production

The wool industry is growing as more people want natural fiber carpets. It’s adopting sustainable practices for wool carpet raw material. This includes ethical sheep farming and new ways to process wool. The goal is to protect the environment and treat workers fairly.

Ethical Sheep Farming

Wool producers are focusing on the sheep’s well-being. They use methods like:

- Rotation grazing to keep pastures healthy

- Less use of harmful chemicals

- Shearing that’s kind to the animals

Eco-Friendly Processing

The wool carpet processing world is getting greener. It’s using:

- Water recycling to save water

- Clean energy like solar and wind

- Waste programs to reuse or recycle

| Sustainable Wool Initiative | Description |

|---|---|

| Responsible Wool Standard (RWS) | A global program for animal welfare and green practices in wool |

| Cradle to Cradle (C2C) Certified | A certification for safe and sustainable products, like natural fiber carpets |

These steps help the wool industry make wool carpet raw material better for the planet and people.

Wool Blending and Yarn Creation Process

Making luxurious wool carpets is a detailed process. It involves blending different wool types and spinning them into strong yarns. Carpet makers pick and mix various wool fibers for the right softness, resilience, and color.

Common Blend Ratios

Blending wool is an art in carpet making. Makers often mix top-quality wool from places like Australia, New Zealand, and the US. They aim for a mix that balances softness, strength, and color well. For example, they might use 80% New Zealand wool and 20% Australian wool. Or, they might blend 60% Merino with 40% Corriedale wool.

Spinning Technologies

Modern spinning tech is key in making carpet yarns. It turns wool blends into strong, beautiful yarns. From old ring spinning to new air-jet and friction methods, each has its own benefits.

These advanced techniques make yarns that last long. They can handle lots of foot traffic and still look great for years.

FAQ: Wool carpet raw material

What makes wool a premium raw material for carpets?

Wool is top-notch for carpets because of its natural strengths. It’s durable, resilient, and keeps warmth in. Its special crimp and scale structure also make it great for places with lots of foot traffic.

How does the chemical composition of wool fibers contribute to their suitability for carpets?

Wool’s makeup is key to its carpet-worthiness. It’s full of proteins, lipids, and other natural stuff. This mix gives wool its strength, flexibility, and ability to resist stains and water.

What are the environmental benefits of using wool in carpet manufacturing?

Wool is good for the planet. It’s renewable, biodegradable, and has a smaller carbon footprint than synthetic fibers. Plus, it’s flame-resistant, cutting down on chemical use in carpet making.

Can you explain the different steps in the journey of wool from sheep to carpet?

Turning raw wool into carpet involves several steps. First, the wool is sheared, then cleaned and carded. Next, it’s spun, woven, and finished. Each step is crucial for quality and consistency.

How do the quality grades of wool affect the performance and appearance of carpets?

Wool quality greatly affects carpet quality. Higher-grade wools, like Merino, make carpets softer, last longer, and keep colors better. Lower-grade wools might make carpets less durable and coarser.

What are the unique requirements for wool used in traditional Persian carpets?

Persian carpets need special wool for their quality and design. Persian wool is finer, softer, and more shiny than other types. Its unique crimp allows for detailed patterns and high knot density.

How have modern manufacturing techniques improved the production of wool carpets?

New tech has made wool carpet making better. Automation, computer weaving, and advanced finishing have improved quality and efficiency. This keeps wool carpets looking and feeling great without breaking the bank.

What factors influence the price of wool carpet raw materials?

Many things affect wool carpet raw material prices. Market demand, seasonal changes, and global economics play big roles. Quality, region, and processing methods also impact costs.

How are sustainable practices being implemented in the wool production for carpets?

The carpet industry is going green. It’s using eco-friendly farming, ethical shearing, and green processing. This includes renewable energy, water saving, and recycling to reduce waste and environmental impact.

Can you explain the process of blending different types of wool and creating carpet yarn?

Blending wool types and making yarn is a careful process. It involves picking and mixing fibers for softness, durability, and color. Advanced spinning turns these blends into high-quality yarn for carpets.